Modification of cellulose fibre

2021-11-29

In recent years, colleagues have done a lot of research work on improving the utilization of reactive dyes. The results show that the modification of the molecular structure of the dye itself is difficult to achieve a high utilization rate, because the hydrolysis of cellulose fibre cannot be overcome. However, the dyeing problem of reactive dyes and cellulose fibre can be improved from the modification of cellulose fibre and the improvement of the reactivity of dyes and fibres. This article reviews and discusses the chemical modification and cross-linking dyeing of cellulose fibre from the perspective of reactive dyeing.

1. Amination modification of cellulose fibre

The electrophilic center of reactive dye-dyed cotton fiber is on the dye, and the nucleophilic center oxygen anion is on the fiber. The newly-emerged fiber modification dyeing puts electrophilic centers on the modified cotton fibers, and the nucleophilic centers are on the dye molecules; the adsorption of cellulose fibers to anionic dyes is greatly enhanced after being modified by quaternization. The dyeing rate of cellulose fibre can even be close to 85% to 98%, so that reactive dyes can also dye fabrics under neutral or salt-free conditions.

1) Amino or aminoalkyl modification of cellulose fibre

After the cellulose fibre is connected with aminoalkyl groups, not only the reactivity with reactive dyes is greatly enhanced, but also after being protonated in an acidic medium, quaternary ammonium cations are formed, which can position and adsorb dye anions. A typical example of this type of reaction is 2-aminoethyl cellulose ether cell-o-CH2CH2NH2 obtained by treating with ethyl 2-aminosulfate at 130° C. and reaction time of 15min. Amination is most often carried out by the reaction of haloalkylamines with cellulose. For example, the hydrochloride of chloroethyldiethylamine reacts with cellulose fibre to produce diethylaminoethylcellulose: cell-o-CH2CH2N(C2H5)2. This modified fiber is highly reactive to reactive dyes.

2) Quaternary ammonium group modification of cellulose fibre

Activating and modifying cellulose with reactive quaternary ammonium compounds can connect quaternary ammonium groups to fibers, which greatly changes the dyeing properties of fibers. A typical example is treating cotton fibers with epoxy trimethylamine quaternary ammonium compounds, which can greatly improve the reaction speed of fibers and reactive dyes, and can also be neutral and salt-free dyeing. Its modified cotton fibers have high directness to acid, direct and reactive dyes. Reactive dyes can be fixed under neutral and salt-free conditions (100°C). When the amount of modifier is high to a certain extent, the modified fiber can absorb the dye in the dye liquor, and the dye uptake rate can reach almost 100%.

3) N-heterocyclic group modification of cellulose fibre

A typical example of such modification is linking nicotinic acid substituents to cellulose molecules. During the reaction, the pH value is 8, and it is baked at 200 °C, and the nicotinic acid group is connected through the ester group. During the reaction, hydrolysis also occurs, and niacin is released. However, the presence of niacin can accelerate the fixing reaction of reactive dyes and fibers, because it can act as a catalyst for nucleophilic reaction. In the dyeing process, this modified fiber, like the aforementioned tertiary amine-based modified fiber, can play an autocatalytic role in the dyeing process and accelerate the color fixing speed. Therefore, it can be fixed under salt-free and neutral conditions. In fact, even in weak acidity (pH=3), it has high fastness to fastness at 80℃ and good fastness to washing.

4) Methylol acrylamide and amination modification of cellulose fibre

After treating cellulose with methylolacrylamide (NMA), a compound containing methylolacrylamide group, active fibers can be prepared: cell-o-CH2NHCOCH=CH2. NMA activated cotton can react with alkyl sulfamic acid dyes to form chemical bonds. Alkylaminosulfonic acid dyes can be prepared from ProcionH type dyes.

5) Modification of cellulose fibre by nitrogen-containing cross-linking agent

Most of the crosslinkers or resins of cellulose fibre fabrics contain nitrogen atoms or amine groups. Their presence, like the amination of cellulose fibre described above, also improves dyeing properties. After treating cotton fabrics with trimethylol melamine, there is a high uptake to direct dyes even in an acid bath. This is all related to the aminoalkyl groups in their molecules. If a certain amount of amine compounds is added when the resin is baked, the finished fabric is dyed with anionic dyes, and the fixation rate or dye uptake rate is high. For example, after cotton fabric is treated with common DMDHEU resin and hydroxyethylamine, and baked at 150℃ for 3min in the presence of catalyst, its dyeability will be greatly enhanced. Even in acid bath (pH=3.0~3.5), anionic dyes have high dyeing rate.

Latest news

About LVJIAN

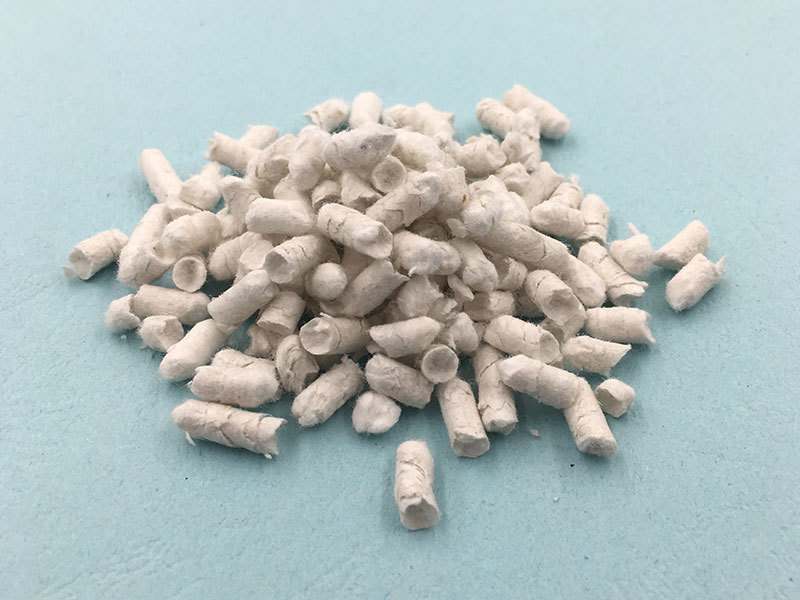

Founded in 2003, LVJIAN is a company that researches, develops and produces high quality natural organic fibers. With the mission of "create value-added products that are conducive to social development, economical and environmentally friendly",

View More+LVJIAN has developed the "green" function of plant materials with advanced fiber technology and applied it to construction chemicals, road construction, organic filter aid, animal nutrition, pet litter and other industries.

Copyright © 2022 Wuxi Lvjian Technology Co., Ltd www.300.cn Changzhou SEO Business license

sanjo@jssqzn.com

sanjo@jssqzn.com

Message

Message